Royal Enfield takes its twin to dirt track (Brandon lajoie/)After 56 years off, Royal Enfield is going racing again—dirt-track racing. This is a company that built its first motorcycle in England in 1901, and thanks to globalization is now owned by Eicher Motors, an Indian company. The bikes are manufactured in India, but designed by an R&D center near Leicester, England. Royal Enfield’s recently introduced 650 parallel twin model has sold strongly, and its compact engine, revealed in 2018, nicely fits the dirt track mold. The shocker is that its US development rider, Johnny Lewis, was able to put the RE prototype on the top box at an American Flat Track (AFT) Production Twins event in October of 2020.

Royal Enfield’s traditionally styled air/oil-cooled twin has sold well worldwide; the attractive and reliable general-purpose middleweight goes for the knockout price of around $6,000. The RE product line, including the Himalayan and Bullet models, outsold Harley-Davidson globally in 2015.

Royal Enfield wowed the crowd at the 2019 European EICMA show with a dirt-track-styled custom built around the 650 engine. It was so enthusiastically reviewed that the company decided to give racing a whirl. A powered-up 750 version of its twin was put into a dirt-track frame built by England’s Harris Performance Products (another Eicher-owned company, which has built MotoGP chassis for the Kenny Roberts team). In the hands of American dirt-track racer and trainer Johnny Lewis the bike evolved rapidly enough to achieve a win.

The latest dirt-track chassis in the versatile build jig. (Brandon lajoie/)Adrian Sellers, RE’s tech center industrial design boss, arranged two Google Meets between myself and the chassis and engine people behind this project to discuss how the project came into being and to help me understand its unusually rapid evolution.

Sellers told me they chose dirt track because, while roadracing’s popularity has declined, dirt track is accessible and attracts many intrigued new fans. Dirt track has become cool.

“We did a bit of drag racing in Europe, and ran a bike at Bonneville—that got (management) comfortable with racing,” Sellers said. “The good news is, they have money to spend!”

I had seen photos of the bike and was struck by its very short wheelbase. That’s what you see in the classic Harley XR; its wheels are about as close to its engine, front and rear, as they can possibly be. That makes the steering quicker and also maximizes weight transfer to the rear wheel during acceleration.

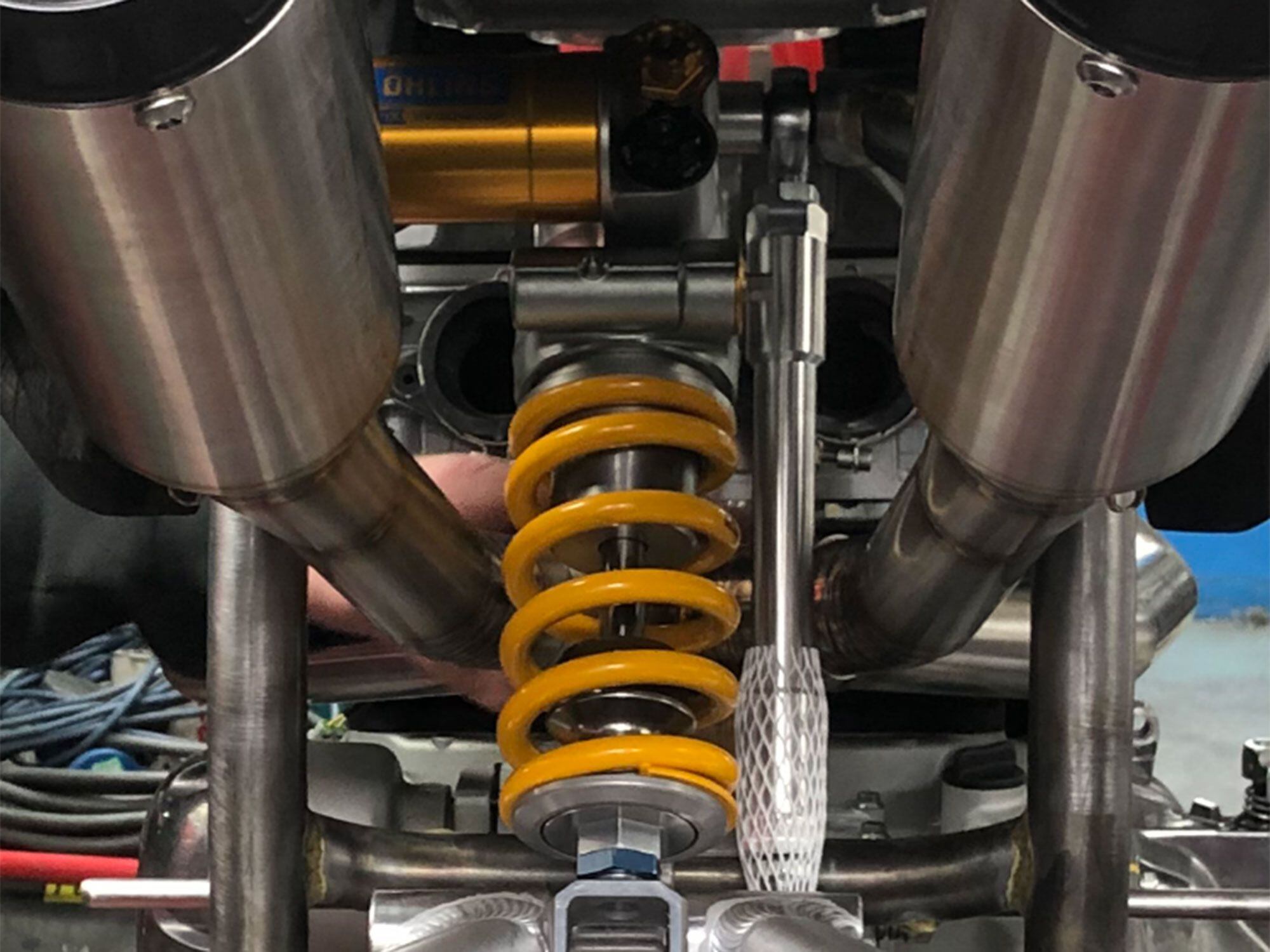

Room for everything—the no-linkage single shock nestles between the pipes. (Brandon lajoie/)“We had no previous dirt-track experience, but we moved quicker with Johnny Lewis,” Sellers said. “It was a case of where do we start? Initially it was a stab in the dark. We thought, We’ll build a lot of adjustment into it and then look for the best settings.”

Steering-head angle can be varied over a range of plus/minus 2 degrees, and steering yokes can change offset (and therefore trail) by plus/minus 4mm. The swingarm pivot height—crucial because it gives control over machine squat/anti-squat during acceleration—can move up or down by 5mm.

“The biggest change was adding flex. Johnny wanted more flex as soon as he rode it,” said Sellers. “We have three chassis now. We started with a cradle frame, but now there’s no structure under the engine.”

The chassis is low-temperature-brazed commercially available 1-1/4-inch 16-gage seamless steel tubing. Brazing, widely used in English tube chassis since its introduction by Rex McCandless on the 1950 factory Nortons, results in reliable joints because it forms smooth, stress-reducing fillets. Suspension, for the moment, is Showa up front and a single TTX 36 Öhlins unit at the rear.

“Normally, single-shock rear suspension can provide a different feel by changing the link,” Sellers said. “But at Johnny’s request, now it has a direct (linkless) shock.”

Wheels are spidery 16-spoke units from Roland Sands Design, machined by Performance Machine from forged billets, accepting the dirt-track standard “Barnes style” quick-change sprocket and brake disc carriers.

This bike is short! Swingarm pivot height can be varied to control squat/anti-squat via alternative inserts. (Brandon lajoie/)Digital communication, the ability of the principals to talk face-to-face and exchange data at any time, has made a big difference to this extremely international program.

Although the (originally) 78.0mm bore by 67.8mm stroke parallel-twin engine evokes the visual flavor of Royal Enfield’s British twin past, it is in fact a modern design in international style. The forged steel crank has three main bearings, whereas traditional British twins had only two, and the crankpins are set at 270 degrees rather than 360. Not only does this give the exhaust note the attractive syncopation of a V-twin, it also reduces the large, twice-per-revolution inertia torques of traditional British twins, whose pistons start and stop together and cause a cyclic variation in crank speed. (Each time the pistons are accelerated from rest, the energy must come out of the crank, slowing it. When they decelerate again to a stop at TDC or BDC they accelerate the crank.) A gear-driven balance shaft ahead of the crank reduces primary shaking forces. Boring the cylinders out to 83.5mm takes the engine to 750cc. In the head, a single cam operates four forked roller rocker arms to control eight valves whose stems are set at a 38-degree included angle. Stock pistons are almost completely flat.

Stock power of the engine is 47 hp at 7,250 rpm. Now the question becomes one of doubling that power to make the engine competitive in AFT. Can it be done? Can it be done reliably?

Rider Johnny Lewis with the very compact, mass-centralized RE. Note below his left hand one of two high-mounted oil coolers. (Brandon lajoie/)The second video meeting addressed these questions. “The problem is getting the revs up where the competitors’ engines are,” said Steven James of RE’s engine team. That means, in round figures, 10,000 rpm.

“And not letting the head get too hot,” components and bottom end specialist Haydn Robinson added.

A look at the stock bike reveals a large oil cooler; the dirt-tracker has two of them to remove heat from those parts of the engine not reachable by cooling air. Therefore cylinder-head cooling is shared between air and oil.

This engine’s 67.8mm stroke is longish, but as Kawasaki has shown with five consecutive World Superbike titles from its rather long-stroked ZX-10RR base engine, a longish stroke is not a disadvantage unless it leads to unreliability. In general it’s easier to achieve fast, efficient combustion in smaller-bore, longer-stroke cylinders than by going in the F1 direction of a huge bore and tiny stroke. To cope with traction on the dirt, a flat torque curve with no surprises is what past winners, such as Harley’s XR, Honda’s RS750, and Indian’s FTR750, have delivered.

The Number 10 RE racing sideways in close company. (Brandon lajoie/)“The production engine has to last hundreds of hours,” James said. “The torque curve was quite flat before we began. We do quite a lot of numerical simulation, (so) getting more airflow is quite straightforward.”

The old path to power was unending testing; build as many as 100 single-cylinder test engines to a variety of specs, dyno them, and develop the winner. Much of that pay-as-you-go cut-and-try can now be eliminated (and the schedule shortened) by intelligent simulation.

Engine team leader Mike Coombs said, “We’ve got access to a good engineering team (in India) and quite sophisticated engine simulation techniques. We use that a lot. The first time on the dyno, we were pretty much where we expected to be.

“The engine—stock—is pretty strong, considering. It’s a relatively recent development, a ‘world’ product.”

OK, let’s speculate. If we push the revs to 9,500 and pick 90 percent of a fully developed engine’s stroke-averaged net combustion pressure, we get a ballpark peak of 97 hp. How hard is 9,500 going to be on pistons? On con-rods? A crude picture can be formed by arithmetic in the form of peak piston acceleration. For this engine, at 9,500 and with a normal rod ratio, we get 4,300 G, which is less than half the highest such accelerations reached in Formula 1′s V-10 era. Seems to me that RE can achieve both the necessary power and reliability.

In dirt-track racing the traction changes as heats and semis roll by, so the bike’s settings have to change with it. (Brandon lajoie/)The Production Twins class in which this bike has run, the class with the greatest variety of machines and riders, is the apparent future of AFT. The Super Twins class that Indian has dominated since 2017 is for purpose-built race engines, so it has become mostly an Indian spec class with maybe a private Harley or Yamaha thrown in.

The reason James spoke of keeping the head from getting too hot is that anything that heats the fresh charge before or during combustion makes detonation more likely. Detonation, an abnormal and destructive form of combustion occurring <i>after</i> the spark has ignited the fuel-air charge, sets the upper limit on engine compression ratio. We want high compression because it raises torque, but the higher we go and the hotter the piston and head operate, the more likely detonation becomes.

The team, ready for action. As Rob Muzzy once said, “Don’t leave anything behind that you might need—the truck can carry it all.” (Brandon lajoie/)“Detonation is not a binary thing, like it’s knocking or it’s not knocking. To get maximum performance, you have to accept some light detonation,” Coombs said.

I remembered Mick Doohan’s crew chief Jerry Burgess talking about the detonation counter—you tuned toward the limit until you had a certain number of counts per lap. Go too far and knock softens the piston and forges it down, trapping the top piston ring. But going for zero counts sacrifices some torque and power.

Consensus is that if you can bring wide, flat torque and close to 100 hp to the series, you’re in with a chance. Making your bike handle? Making it reliable? Making it work on mile, half-mile, and TT? Those are other questions, but they’ll be easier answered with a cooperative major manufacturer smoothing the way.

This shot shows the latest more-flexible chassis—structure under the engine. Also the floating link rear brake caliper that doesn’t hop or chatter the tire when you brake over bumps. (Brandon lajoie/)“We have access to simulations for the durability of parts. What’s the fatigue life of the crank? We have good confidence in components,” Coombs said.

The good result at Daytona last October suggests that at least some handling issues are under control, as observers didn’t think that win came from horsepower. We want to see starting fields in AFT become deeper and competitive equipment more accessible, so we welcome Royal Enfield to flat track racing. Romantics want flat track bikes to be developed in private backyards and basements, but realists admit that engine development is a stretch for most Americans. Therefore the shortest path to deeper fields and closer racing is competitive bikes you can afford to buy. That’s exactly what the classic Harley XR was when it first became available in 1972.