2022 Husqvarna Enduro 2T Range

Changes for 2022 on Husky’s two-stroke bush-bashers primarily focus on new suspension tunes in the WP XPLOR forks and XACT rear shock along with new Braktec hydraulic clutch and braking hardware. The existing Husky brake and clutch set-up was pretty damn awesome so it will be interesting to see if the changes have improved them even further. New GSK wave disc rotors are another change.

The suspension changes include a new oil bypass system in the 48 mm outer fork tubes while the shock seals are now reduced in hardness which Husky claim improves feedback and damping consistency. The forks have 30-click adjusters, compression in the left leg and rebound in the right. The linkage set-up on the rear is the same as used in Husky’s TC/FC motocross range.

CNC machined triple clamps are anodised black and position the forks in a 22 mm offset while the bars are adjustable.

Traction control is selected on or off by the switch and functions by analysing throttle input from the rider and the rate at which engine RPM increases. If the RPM increases too quickly, the engine management system (EMS) registers a loss of grip and reduces the amount of power to the rear wheel to maintain maximum traction. Additionally, all two-strokes are fitted with a standard map switch to allow selection between two ignition curves based on conditions or rider preference.

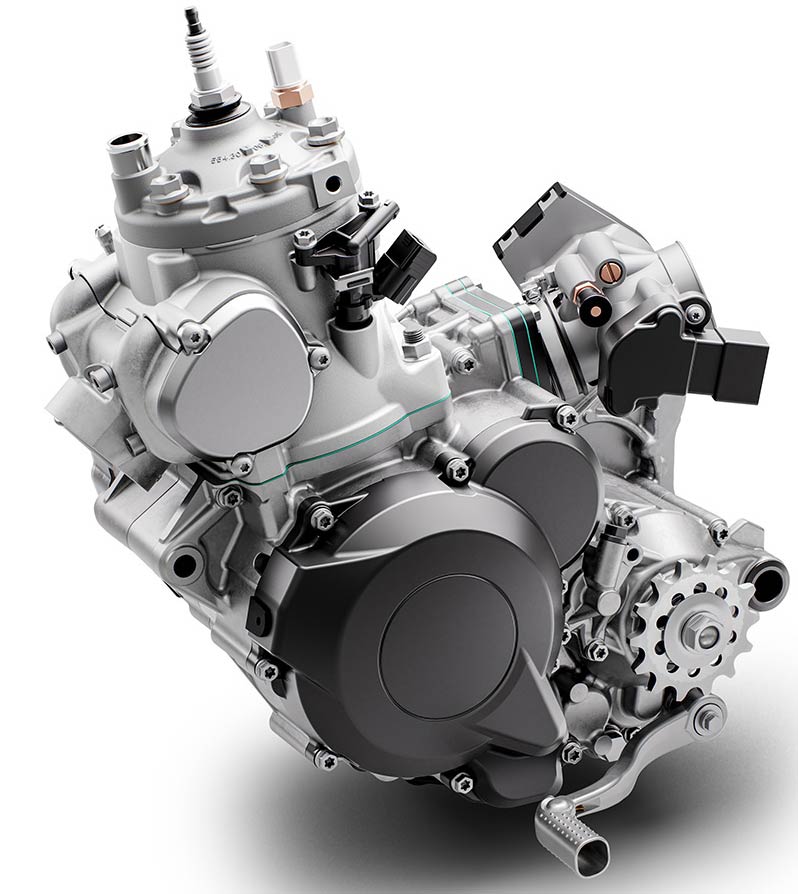

The EMS features an electronic control unit (ECU) on the two-strokes, which is responsible for a number of functions. The unit determines ignition timing and amount of fuel and oil injected. It also receives information from the throttle position sensor, ambient air and intake pressure sensors as well as crankcase pressure and water temperature sensors to adapt values and make corrections for automatic temperature and altitude compensation. Prior to fuel injection, this would have meant changing carburettor jets.

The two-strokes use a 39 mm throttle body which regulates the amount of air entering the engine via a butterfly operated by dual throttle cables connected to the handlebar throttle assembly. Unlike four-stroke throttle bodies, fuel is not introduced at this point, but rather two-stroke oil is mixed with the air entering the engine to lubricate the crankshaft, cylinder and piston. Additionally, a throttle position sensor (TPS) relays airflow data to the ECU which in turn calculates the amount of oil and fuel delivered to the engine while a bypass screw regulates the idling speed and a cold start device opens an air bypass for cold starts.

Tailored specifically for each model using an innovative 3D design process, the two-stroke header pipes feature advanced geometry and performance. The TE 250i/300i header pipe offers more ground clearance making it less susceptible to damage, while a corrugated surface makes the header pipe more durable to rock damage and other hazards found on the enduro trail. The two-stroke mufflers also feature an aluminium mounting bracket and advanced internal construction for excellent noise damping and weight saving.

All TE models come with electric start as standard. The system uses a compact and lightweight Li-Ion battery which is 1 kg lighter than a conventional battery. Additionally, the wiring harness concentrates all needed electrical components into a common area below the seat for easy accessibility.

The radiators are made from high-strength aluminium and designed using CFD (computational fluid dynamics) to channel air through them more efficiently. The cooling system is intelligently integrated with the frame, eliminating the need for additional hoses. The large centre tube running through the frame reduces pressure at this point, allowing for a consistent coolant flow.

While the four-strokes get a radiator fan as standard, this is an optional extra on the two-strokes.

An 8.5 litre polythene fuel tank incorporates a quick release filler cap and an integrated fuel pump.

The airbox is designed with precisely positioned inlet ducts aimed at preventing air deformation to ensure maximum airflow and filter protection. The air filter is easily accessed, without tools, by removing the left side-panel. Easy maintenance is guaranteed by the Twin Air filter and filter cage design featuring a simple fail-proof mounting system for safe and accurate filter installation.

Black high-strength alloy rims by D.I.D with laser engraved logos are coupled to CNC machined hubs using lightweight spokes and silver anodised aluminium nipples. The nipples incorporate an advanced design reducing the frequency of spoke checks and maintenance.

Rugged grey and electric yellow graphics look mint while the ergonomics are tailored to deliver comfort and control.