BMW single-cylinder models such as the G 310 R roadster appear slated to get ShiftCam variable valve timing and lift. (BMW/)Variable valve systems are becoming more common on motorcycles and BMW’s ShiftCam stands out for being a clever and relatively simple solution among the current designs. It’s already in use on the R 1250 boxer twins and the S 1000 RR’s inline-four. Next target in the BMW line? A new patent application shows that BMW’s G-series single-cylinder range including the G 310 R and G 310 GS are likely to get the technology.

How BMW ShiftCam Works

The ShiftCam system does exactly what its name suggests. It shifts the inlet camshaft to bring one of two possible cam profiles into contact with the inlet valves, altering not only the cam timing but also the valve lift. The benefit is that the engine can have a conservative cam profile for low revs, with less lift (how wide the valve is opened) to increase the gas velocity into the combustion chamber, increasing torque at low revs. The low-rpm cam lobe also has less timing advance and duration, reducing overlap (the period when the inlet valves open before the exhaust valves have closed). That means there’s less time for unburned intake charge to escape into the exhaust, improving efficiency and reducing emissions.

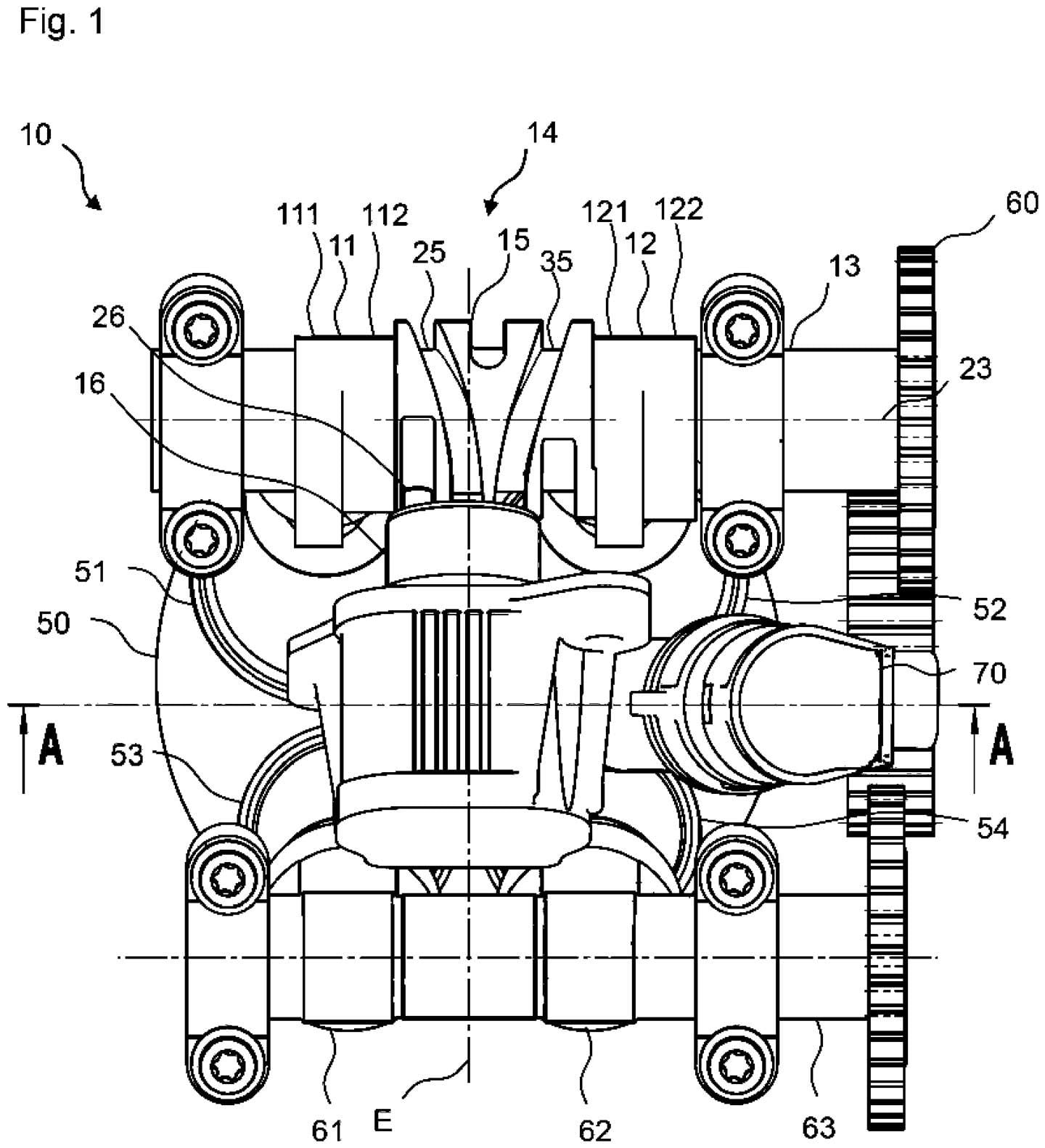

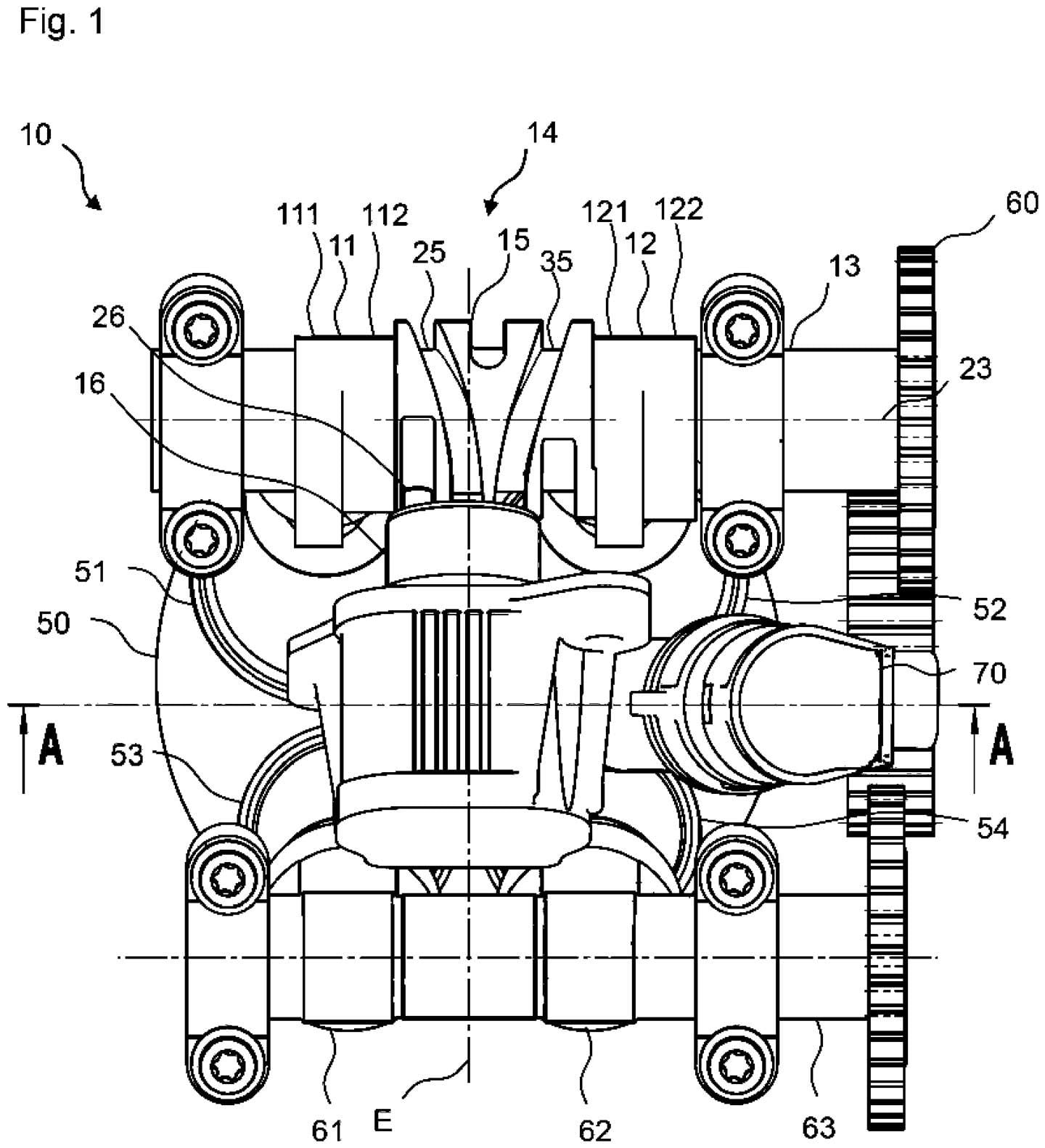

BMW ShiftCam patent drawings show solenoid in the middle of the intake cam, where it works on the spiral grooves to switch between low-speed and high-speed cam profiles. (BMW/)At higher revs, when the valves are opening and closing faster, that low-lift, short-duration cam profile can’t get enough air-fuel mixture into the combustion chamber in the brief window when the valve is open, so a more aggressive cam profile is brought into play by sliding the camshaft laterally. This profile has much more valve lift and duration (how long the valve is open for), letting more air and fuel into the cylinder to increase peak power and maximum torque. Because the engine is revving higher, the valve timing can also be advanced, opening the inlet valve earlier and increasing overlap and there still won’t be enough time for the unburned fuel to escape into the exhaust, so emissions and efficiency remain good.

Other Types of Variable Valve Timing and Lift

The principle is the same as other cam-switching VVT systems, the most famous being the Honda VTEC setup used on the VFR800 first in 2002 and on its cars for more than 30 years, but BMW’s method of achieving the effect—by sliding the camshaft to swap lobes—is unlike other brands’ solutions and unique in motorcycling. It’s achieved by having a slidable camshaft (on the R 1250, the S 1000 version has a slidable sleeve over a splined central section of the camshaft). The movement is controlled by solenoids that push pins into a spiral groove machined into the camshaft. When a pin is engaged, the spiral makes the shaft move to one side. The spiral groove means the cam lobes will swap over when the intake valve is closed, so there’s no chance of a mechanical clash of trying to change the timing during an inlet stroke.

Top view of BMW’s new ShiftCam design for its single-cylinder engines shows the actuation grooves clearly. Also note the gear drive with idler. (BMW/)Other VVT systems such as the one used on Ducatis use oil pressure in chambers to vary the cam position versus the driven sprocket. Ducati has actuators (controlled by solenoid valves and oil pressure) on intake and exhaust cams for more timing flexibility, but lift is not varied.

What’s Different About ShiftCam for the New Singles

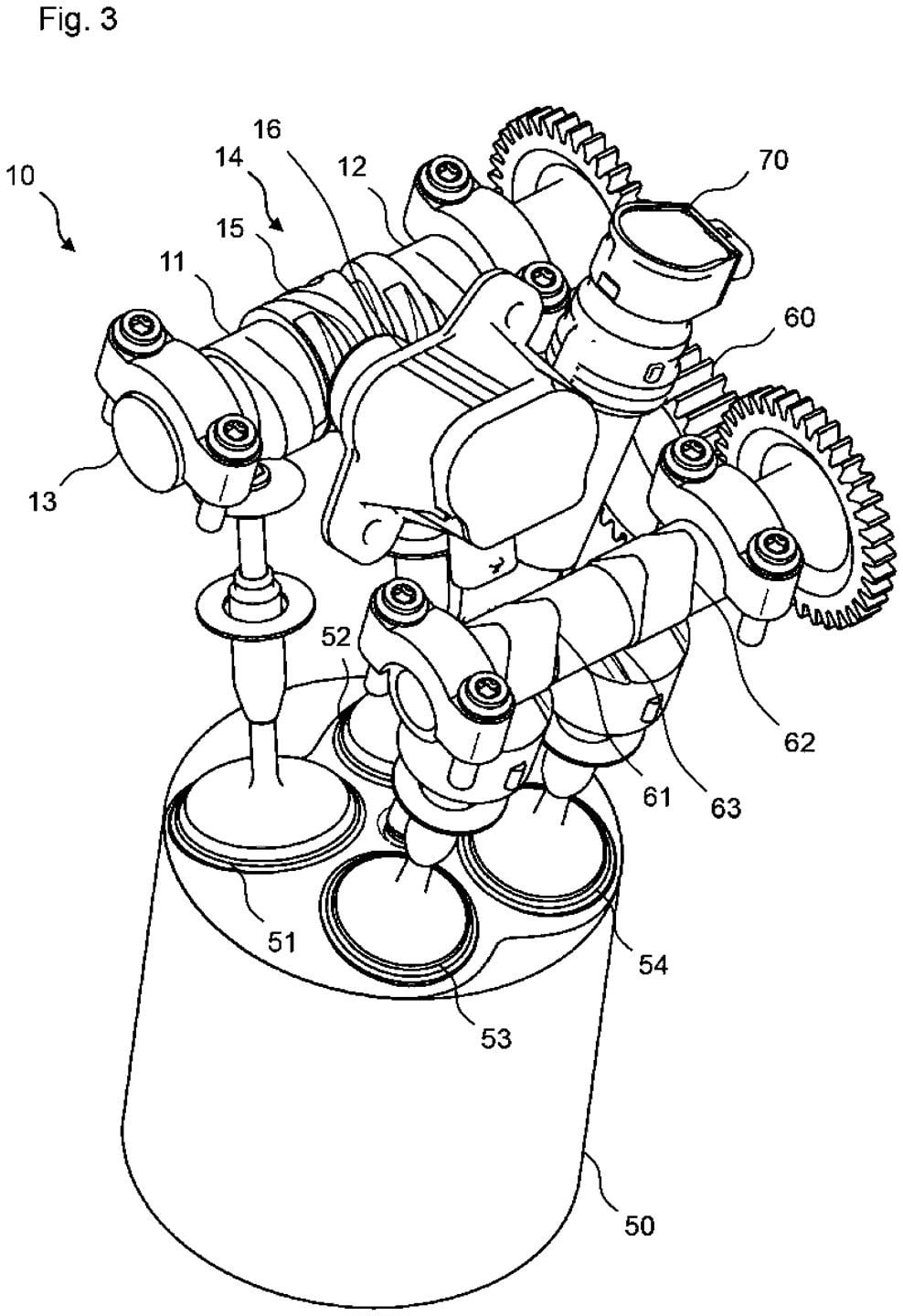

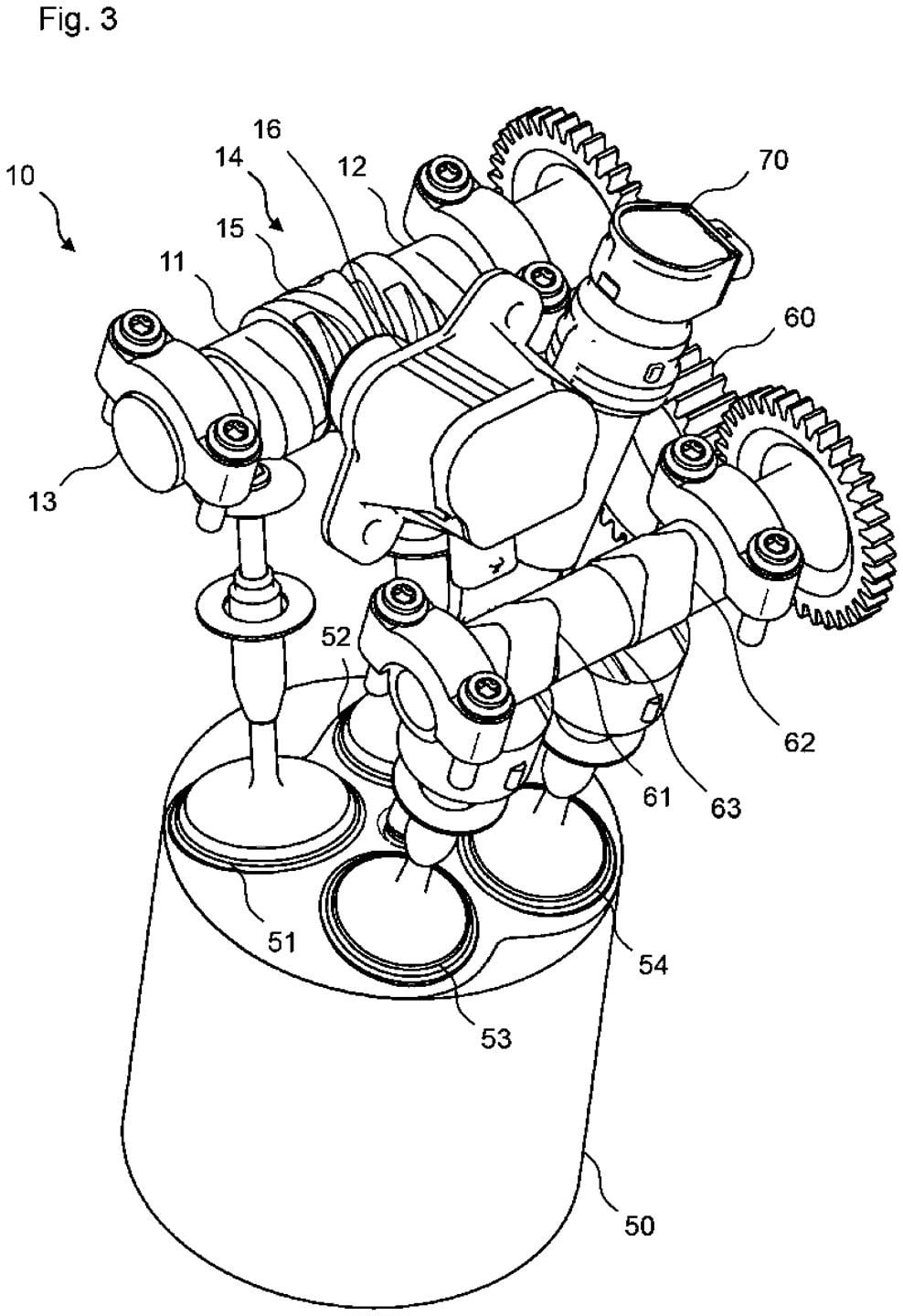

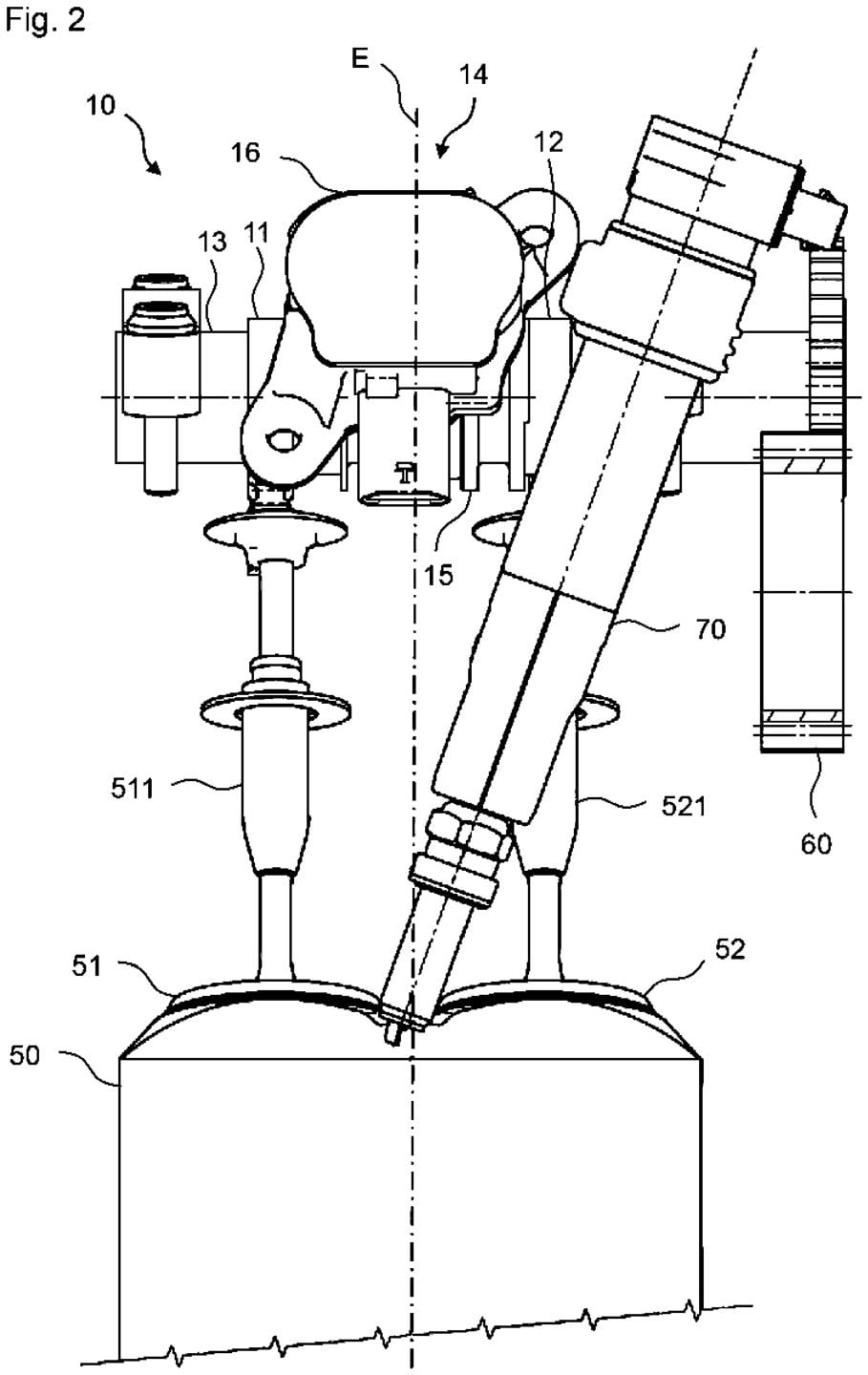

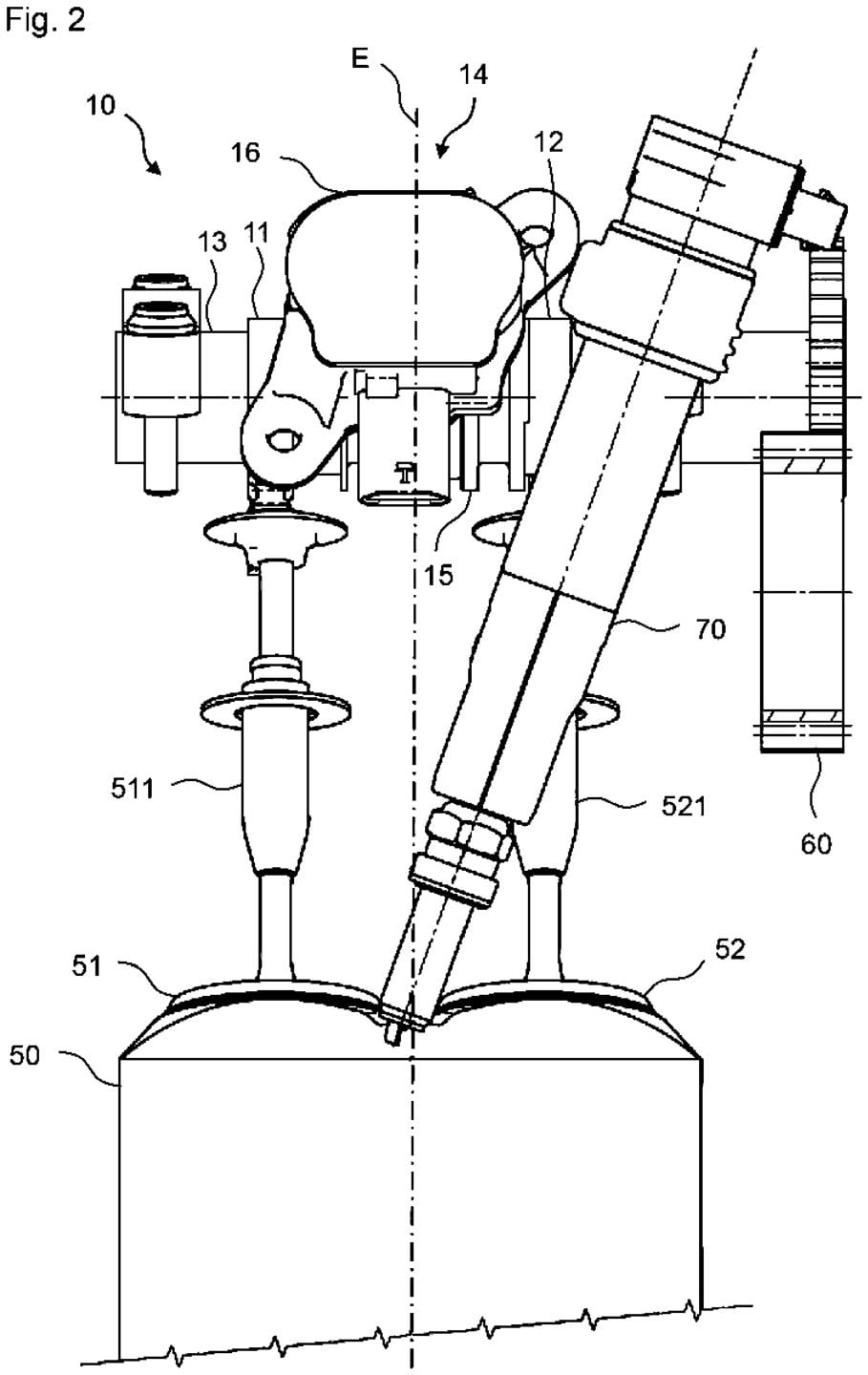

While the overall idea is the same as the ShiftCam system in the latest R 1250 and S 1000 engines, the single-cylinder in the new patent is more compact. It’s made smaller by fitting the solenoid actuator between the two intake valves—it’s a four-valve engine—so the camshaft doesn’t need to be any longer than a conventional design. Putting the actuator in the middle does mean the spark plug has to be fitted at an angle, and because the whole camshaft slides, there’s an additional idler gear connecting the intake and exhaust cams, rather than having a direct chain drive from the crankshaft to the camshafts.

With the solenoid and actuation spiral grooves at the center of the intake cam (rather than end mounted as on the R 1250 GS), the spark plug and stick coil must be angled for clearance, as this patent illustration shows. (BMW/)The patent specifically says that the new engine is a single-cylinder. At the moment, BMW’s only singles are the G 310 range, made in India by TVS on BMW’s behalf and including the G 310 GS, G 310 R, and G 310 RR, and the C 400 scooters manufactured in China by Loncin. The patent could relate to any of those bikes, with the G-series models being a more likely target, or it could be an indication that BMW is developing an entirely new single-cylinder engine, perhaps a larger, higher-performance one to plug the gap between the G 310 bikes and the F-series parallel twins.